wye delta starter sequence of operation

Low Starting Torque. PSI Power Controls is absolutely committed to bringing your commercial business the best in product electrical equipment.

Star Delta Starter Explained Working Principle Youtube

The star-delta wye-delta starting method controls whether the lead connections from the motor are configured in a star or delta electrical connection.

. And Starter module remain powered 69 Current Overload Protection. A motor starter is ideal for larger equipment that generates considerable voltage or can generate a surge in power and today well be talking about specifically the application of Wye Delta open transition starters. For wye-delta starting peak amps equivalent of trapped flux 13 LRC 472 LRC707 Therefore actual total peak amps 224 X LRC 746 LRC 2986 X LRC.

Fuse or circuit breaker For short circuit protection. A fact that is covered in more detail in the section called Sizing Power Conductors and Contactors for Wye-Delta Motors which begins on page 49. Wye systems have five wiresthree hot one neutral and one ground.

When converting a Wye-Delta system to an RVSS the cables from. Main start and run. Star-Delta Starter can be used only for low to high power three phase induction motors.

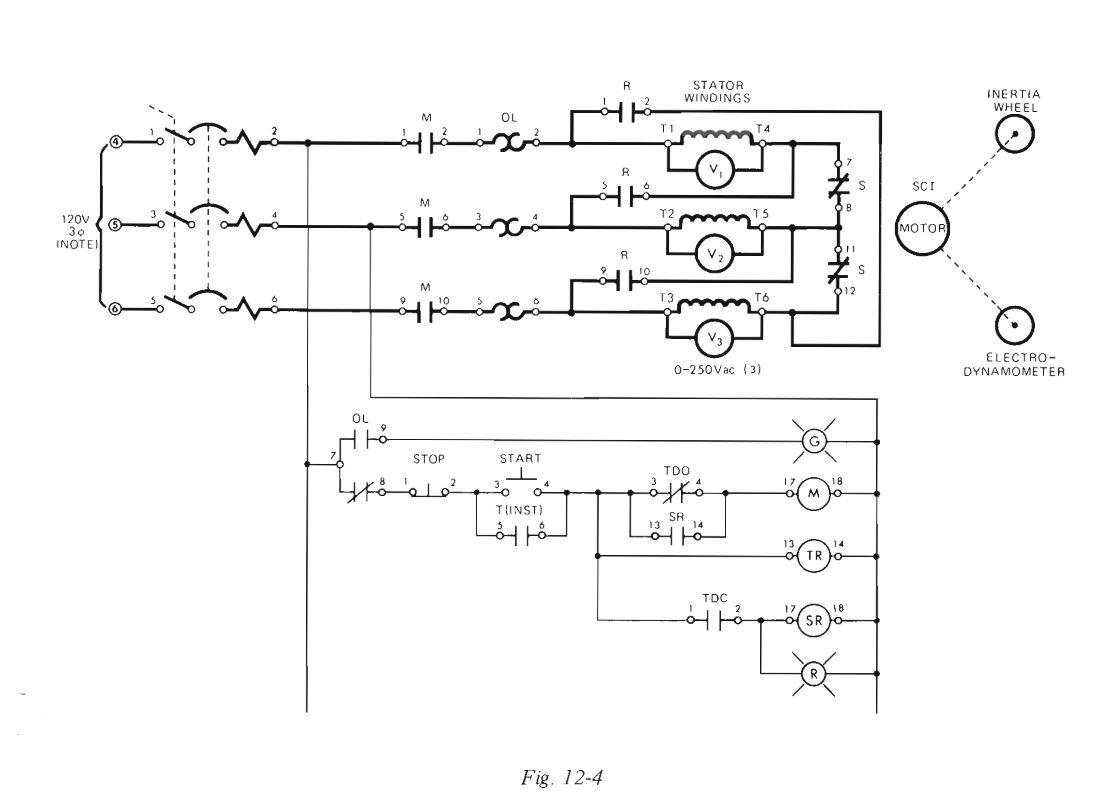

Overload relay- For overload protection. Sequence of operation overview. Figure below a and b shows the power and control circuit of a WYE-DELTA Reduced Voltage Starter.

The timer TR will delay the opening and closing of its normally closed contact TR 8-5 and normally open TR 8-6 respectively when its coil terminals TR 2-7 is. Star-delta timer to switch between star and delta connection. CDHFG sequence of operation.

The resistor bank on a closed transition Y Delta starter actually carries the load during the closed transition. CDHFG sequence of operation. Automatic Star Delta Starter with Timer for 3-Phase AC Motors.

Low Starting Torque. They are in the circuit for less than 110 th of a second. Lead 2 lag 1.

68 Momentary Power Loss MPL Protection. In comparison a standard single-voltage delta motor has three leads that are marked T-1 through T-3. Wye StartDelta Run - Initially the motor will start monetarily on the Wye connection and then switch to the Delta Run for continuous opera-tion on either high or low voltage.

A star delta starter consists of a following parts. This class covers identifying Components Sequence of operation along with the Maintenance of the Wye Delta Starters. Overload trip time.

B-Explain in your words the sequence of operation of the contactors in Wye Delta Starters 2 Compare between the demand limiting system operation with the opical low and high voltage centrifugal chiller installation 3. Momentary power loss DynaView. The reduction of the high motor current causes a reduction of the starting torque of the motor.

CDHE CDHF and CDHG sequence of operation. The starter can be used with all squirrel-cage induction motors that are delta-connected for normal operation. The initial connection should be in the star pattern that results in a reduction of the line voltage by a factor of 13 577 to the motor and the current is reduced to 13 of the current at full.

The control of the contactors is by the timer K1T built into the starter. 2KMmain closed and KM2KM1open in dis state moter runs as generator 3MAin Delta closed and star is open motor connects in full load Power Circuit of Wye Y Delta Δ Starter. Parts of a star-delta starter.

After a period of time adjusted by - timer current sensor etc or when the motor reaches approximately 80 full speed contactor 2M 2S are energized connecting the motor in a delta configuration. Test and start timing sequence. In actuality six power conductors are required from a wye-delta starter a wye-startdelta-run motor.

By connecting the delta windings of the motor in wye for starting the voltage on the motor windings is reduced by 333 and the starting current and torque by 666. Once the motor reaches or approaches its operating speed the wye connection is. The star-delta wye-delta starting method controls whether the lead connections from the motor are configured in a star or delta electrical connection.

CDHEFG sequence of operation. Star-Delta starter is the simplest starting method for reducing the inrush starting current of Induction motor. UCP and Wye-Delta Starter Control Circuits.

The starting current is 33 of full load current for star delta starter. When the start command is issued contactor 1M is closed connecting the motor in a Wye configuration. CVHE CVHF and CVHG sequence of operation.

A single-voltage wye-delta motor typically has six leads that are marked T-1 through T-6. In operation the Main Contactor KM3 and the Star Contactor KM1 are closed initially and then after a period of time the star contactor is opened and then the delta contactor KM2 is closed. Delta Configuration 435 amps x 3 754 amps Æ 307 lbs-ft.

This can be accomplished with a spe-cial Wye Delta Starter or by a series of contactors in a control circuit. The initial connection should be in the star pattern that results in a reduction of the line voltage by a factor of 13 577 to the motor and the current is reduced to 13 of the current at full. KM3KM1 closed or main star contacter close.

The peak starting current is 13 to 26 of full load current. Star-Delta starter circuit design tool. It has reduced starting current and torque.

This will produce less arcing as the the contactors make and break. CDHEFG sequence of operation. The Delta configuration has the three phases connected like a triangle whereas the Wye or star configuration has all three loads connected at a single neutral point.

Equalize starts and hours. Other values can be calculated for various conditions of trapped flux based on time delay. For dual-voltage motors the wye-delta motor Starting Voltage Reduction 480V 3----- 480 173----- 1 173 x 480 0577 x 480 277V.

Reduced Voltage - Sometimes referred to as transformer starting. Contactors For switching. This generator goes into a random non-synchronized electrical position with regard to the power source.

Starting the Wye Delta. The peak starting torque is 33 of full load torque. Delta systems have four wiresthree hot and one ground.

A time delay relay Timer is in the control circuit.

Motor Star Delta Starter Working Principle Instrumentationtools

How To Use Motor Delta And Wye Connection Quora

Star Delta Starter Wye Delta Starters Circuit Working

Star Delta Starter Working Principle Theory Circuit Diagram

Electro Mechanical Star Delta Starter Electrical Engineering Centre

In A Wye Delta Motor Starter Which Type Of Time Delay Is Used Is It An Off Delay Or An On Delay Timer Quora

Automatic Starters For Star Delta Motors

Star Delta Starter Wye Delta Starters Circuit Working

Star Delta Starter Theory And Working With Power And Control Circuit Electrical Technology All About Electrical Engineering

Automatic Starters For Star Delta Motors

Star Delta Motor Starter Explained In Details Eep

Automatic Starters For Star Delta Motors

Control Circuit Of A Star Delta Or Wye Delta Forward Reverse Electric Motor Controller A Basic Industrial Process Automation Control How To Do Guide For Reversible Star Wye Delta Motor Controller

What Would Be The Reason For The Delta Contactor To Not Be Energized In A Star Delta Starter Circuit Quora

Solved This Is A Wye Delta Starting Of A 3 Phase Induction Chegg Com

Automatic Starters For Star Delta Motors

Star Delta Starter Explained In Plain English Electrical4u